Hot tub factory tour

Expert Manufacturing + Industry Leading Components = Hot Tub Quality that Rivals any Brand.

|

|

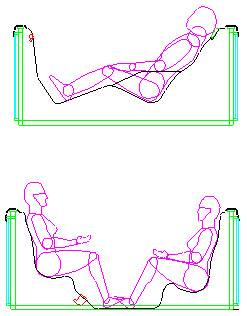

Step 1 - It Begins With The Hot Tub Design Process

|

|

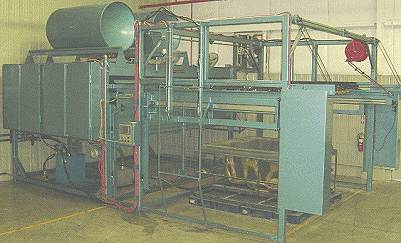

Step 2 - Vacuum Molding The Hot Tub Acrylic |

|||

| The acrylic sheet is heated to over 400 degrees by a state of the art PLC controlled oven. The oven has over 30 different heat zones that allow the sheet to be heated from the top and the bottom. It is very important to evenly distribute the heat to ensure that the spa maintains uniform color and crisp detail during the forming process.

|

Hot Tub Shell Vacuum Forming - Watch a flat sheet of acrylic form into a hot tub (BellaGrande model shown).

|

||

|

|||

| The heated sheet is then sealed over a ceramic mold and a vacuum system removes the air from in-between the sheet and the mold, drawing the sheet into the final shape of a spa.

|

|||

|

|||

Step 3 - Strengthening The Acrylic Shell of the Hot Tub (A) |

|

|

Step 4 - Hot Tub Acrylic Strengthening Process (B) |

|

|

|

|

|

|

|

|

Step 5 - Meticulous Jet Installation on our Hot Tubs |

| All jets in a our Spas use an L-shaped gasket instead of the standard and cheaper flat gasket. The L-shaped gaskets not only seal the face of the jet to the acrylic surface, they also seal the hole that the jet is installed into, providing Dual Protection Against Leaks. |

|

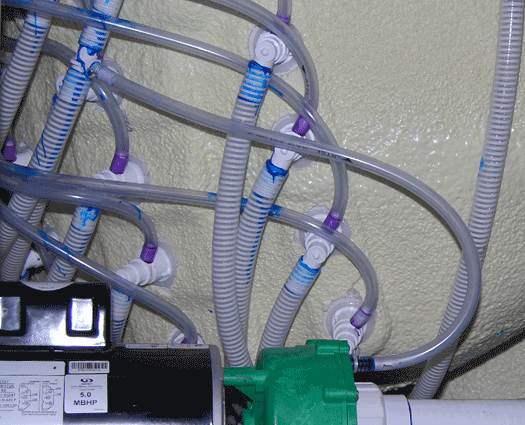

Step 6 - Best Quality Hot Tub Plumbing Methods |

|

|

Step 7 - Structural Wood Hot Tub Frame |

|

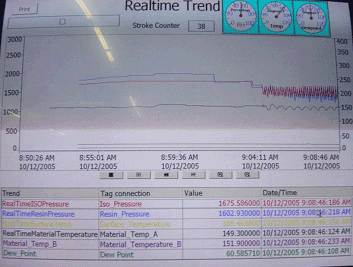

Step 8 - Total Testing of EVERY Hot Tub

|

|

Step 9 - Beautiful Synthetic Hot Tub Cabinet |

|

|

|

Step 10 - Your Completed Hot Tub is Shipped Directly to You! |

|

|

Your new spa is made only when you order it. It isn't sitting around as old inventory. Your spa will go directly from the factory to your home.

|

|

Our Spas are constructed with the highest quality materials and some of the latest innovative manufacturing techniques to ensure that every spa meets our highest quality standards.

Our Spas are constructed with the highest quality materials and some of the latest innovative manufacturing techniques to ensure that every spa meets our highest quality standards.

Loading...

Loading...